Relevant Documents

(633KB)

(633KB)

Background

Micro-Electro-Mechanical Systems (MEMS) are the technology of very small devices. MEMS are made up of components between 1 to 100 micro-meter in size (i.e. 0.001 to 0.1 mm), and MEMS devices generally range in size from 20 micro-meters to a millimeter (i.e. 0.02 to 1.0 mm). They usually consist of a central unit that processes data (the microprocessor) and several components that interact with their surroundings such as micro-mirrors.

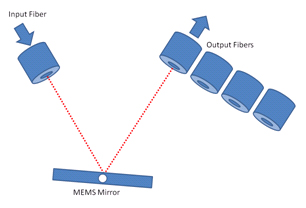

A micro-mirror is a Micro-Electro-Mechanical System (MEMS) in the category of micro-mirror actuators for dynamic light modulation. MEMS mirrors can deflect an optical signal to an appropriate receiver, and by doing so, it can be used as an optical switch.

Figure 1: MEMS mirror as an optical switch

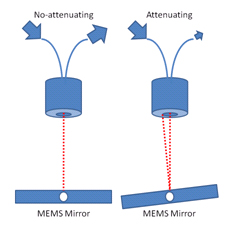

Another simple use for MEMS mirrors is as optical attenuator: the light from the input fiber is partially blocked or attenuated by the MEMS mirror.

Figure 2: MEMS mirror as optical attenuator

Requirement

Depending upon the type of operation, the modulatory movement of a single mirror can be either translatory or rotational, on one or two axes. In the first case, a phase shifting effect takes place. In the second case, the beam of light is deflected. In research and development of these MEMs mirrors or peripheral equipment that uses them, it is necessary to be able to control them.

In most of the implementations, one or two pairs of electrodes control the position of the mirror by electrostatic attraction. In the two pairs case, Each pair has one electrode on each side of the hinge, with one of the pairs positioned to act on the yoke and the other acting directly on the mirror. The majority of the time, equal bias charges are applied to both sides simultaneously.

A 2D square MEMS mirror can be implemented using a comb drive actuators. This implementation usually consists of a movable mirror which can be pulled toward the other electrode (the bigger frame) when applying a voltage difference. The movable electrode is suspended by a mechanical spring. When voltages are applied in each of the electrodes, opposite charges on each one attract each other. This attractive force is larger when the movable electrode is closer to the fixed electrode.

Solution

Tabor Electronics’ Wonder Wave family of Arbitrary Waveform Generators with its four channel models combined with Tabor four channel Signal Amplifier, provide a full range of capabilities for MEMS developers and users, for testing and simulating, control and operation of the miniaturized electro-mechanical square mirrors.

The Tabor Electronics WW2074 with its four synchronized channels waveform generation ability, save cost without comprimizing bandwidth and signal integrity. Combined with the Tabor Amplifiers, users can have a complete solution that reached the required high voltage. These exceptional abilities are perfectly suited for the control and simulation of the MEMS square mirrors operation.

For More Information

To learn more about Tabor’s solutions or to schedule a demo, please contact your local Tabor representative or email your request to [email protected].